Why Chosse Us

Choose Golden Tin Co., Limited for unparalleled tin packaging solutions. We prioritize sustainability with our advanced metal recycling, reducing environmental impact while delivering customized, industry-leading protection for food, cosmetics, and promotional items. Our commitment to eco-friendly practices and innovative designs not only enhances your brand’s appeal but also provides a competitive edge, ensuring your products stand out in the market. Partner with us for a green, adaptable, and cutting-edge packaging experience.

Tinplate Materials

Galvanized material

Galvanized iron is iron or steel that has been coated with a protective layer of zinc to prevent rust and corrosion. This process, known as galvanization, enhances the durability and longevity of the metal, making it ideal for a wide range of applications. Common uses include construction materials, roofing, fencing, and outdoor structures.

Silver glow material

Silver glow material is a type of reflective fabric or coating that emits a bright, silvery sheen. It is commonly used in fashion, safety gear, and decorative items due to its eye-catching appearance and reflective properties. This material enhances visibility in low-light conditions, making it ideal for safety clothing and accessories. Additionally, its unique look adds a stylish and futuristic touch to various products.

Tinplate material

Tinplate is a thin sheet of steel coated with a layer of tin. This combination creates a strong, corrosion-resistant material that is widely used in packaging, especially for food and beverages. Tinplate is known for its excellent formability, making it ideal for creating cans, lids, and other containers. It also provides a barrier against contamination, ensuring the freshness and safety of packaged products.

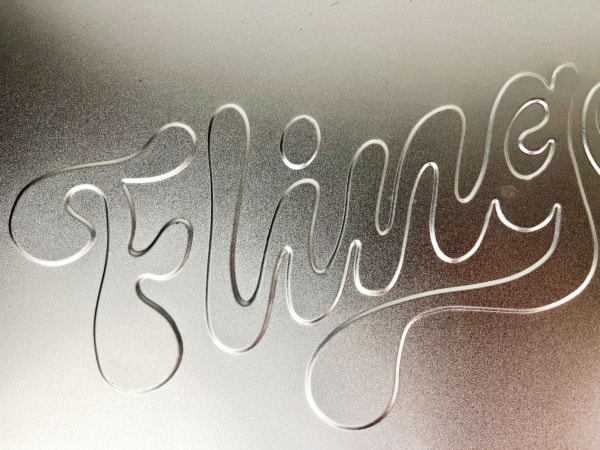

Emboss and Deboss on Tin

Emboss

Flat Emboss

Deep Eboss + Flat Emboss

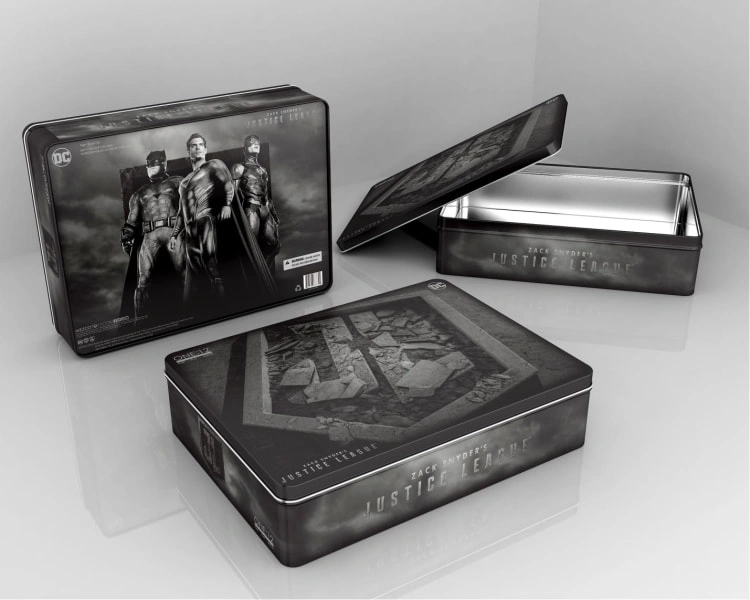

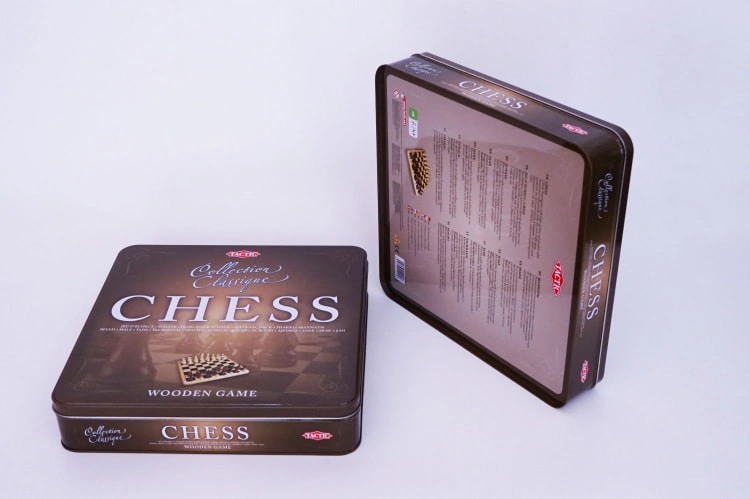

Personalize Your Very Own Tin

Round Shape

Rectangle Shape

Square Shape

Iregular Shape

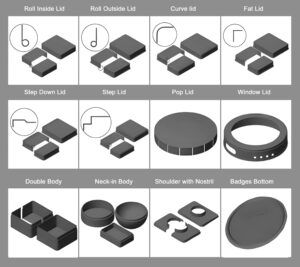

Knowledge Related to Tins: What You Need to Know

Tins are versatile packaging solutions widely used in various industries, including food, cosmetics, and gift items. Made from tinplate or aluminum, tins offer excellent durability, corrosion resistance, and a premium look. They are ideal for preserving the freshness and quality of products, making them a popular choice for packaging chocolates, biscuits, tea, spices, candles, and more.

Why Choose Tins for Packaging?

- Durability: Tins are strong and resistant to impact, ensuring your products remain safe during transportation.

- Corrosion Resistance: The tin coating prevents rust, extending the shelf life of the contents.

- Aesthetic Appeal: Tins provide a high-end look that enhances the visual appeal of your products.

- Versatility: Suitable for a wide range of products, from food to cosmetics and beyond.

- Recyclability: Tins are eco-friendly, as they are 100% recyclable, supporting sustainable packaging practices.

Common Uses of Tins:

- Food Packaging: Chocolates, biscuits, tea, spices, and more.

- Cosmetics: Creams, balms, and lotions.

- Gift Items: Candles, jewelry, and custom gift sets.

- Specialty Products: Collectibles and limited-edition items.

By choosing our high-quality tins, you ensure your products are packaged in a way that preserves their integrity and enhances their market appeal. We offer a range of customizable options to meet your specific needs, including various shapes, sizes, and designs.

Tins You May Like

CR Tin

Irregular Tin

Round Candle Tin

CR Tin

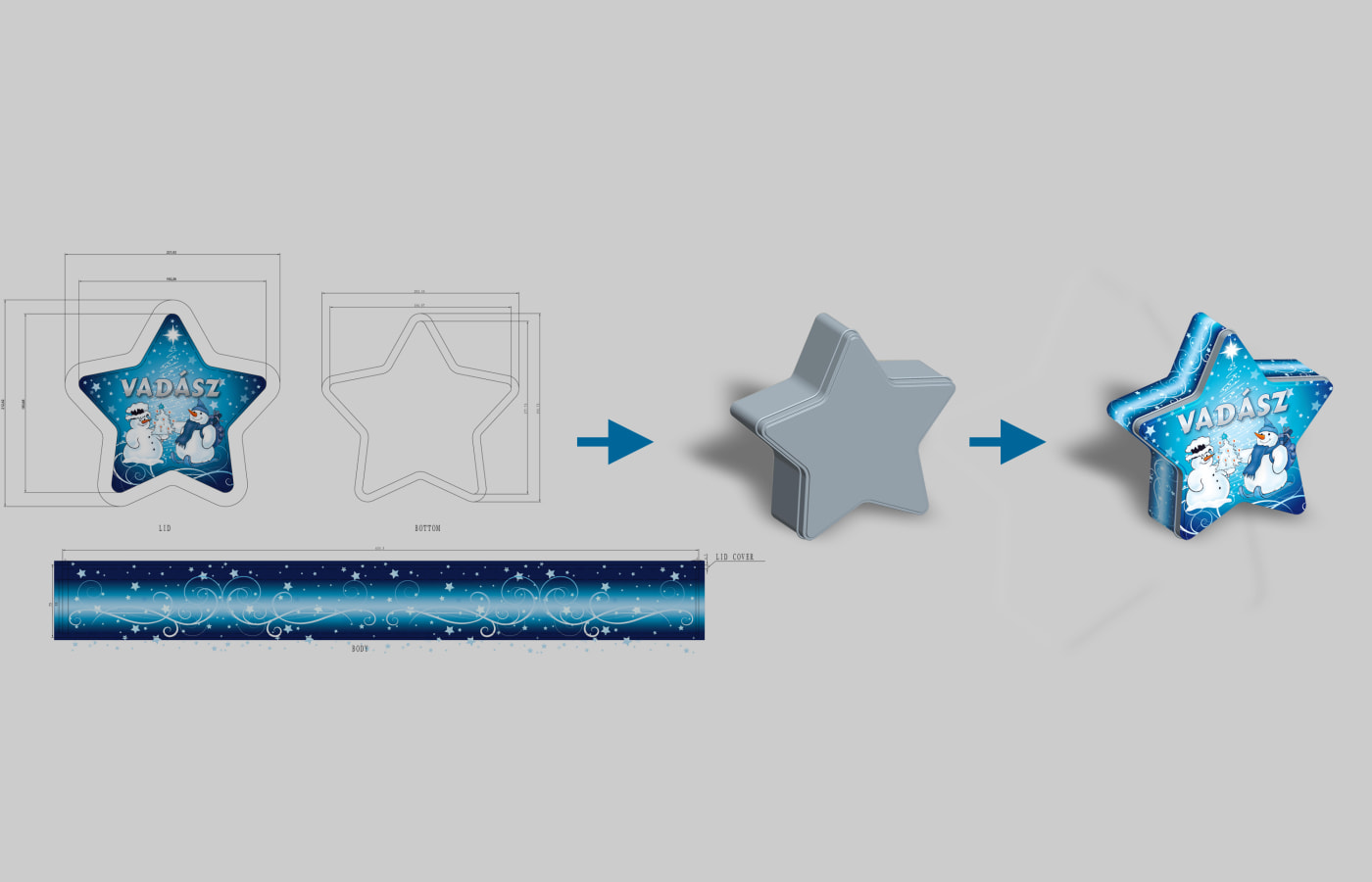

How Tinplate is Converted into a Tin Box

Converting tinplate into a tin box involves several steps. First, tinplate sheets are cut and printed with designs. Next, the sheets are coated for protection. Blanks are then stamped and formed into the box’s body, lid, and base. These components are joined through crimping and folding, followed by rigorous quality control checks. Finally, the boxes are cleaned, polished, and packaged for shipment. This precise process ensures high-quality, durable, and attractive tin boxes for various uses.

![CR tin Secure and Stylish Child-Resistant Tin Packaging for Safe Storage At [Your Company Name], we specialize in innovative child-resistant tin packaging solutions designed to meet the highest safety standards while enhancing your brand's visual appeal. Our child-proof tins are perfect for a variety of industries, including pharmaceuticals, cannabis, and household products, ensuring that safety and functionality go hand in hand. Our child-resistant containers are crafted with precision, employing a patented locking mechanism that is simple for adults to use but challenging for children, effectively reducing the risk of accidental access. Each tin is constructed using high-quality, durable materials that offer excellent protection against contamination and damage, making them ideal for both child-safe packaging and adult use. Safety is at the forefront of our design process, but we do not compromise on aesthetics. We offer custom tin packaging options that allow you to tailor the look and feel of your products to match your brand identity. With advanced printing and embossing techniques, your packaging is not just secure but also visually appealing, enhancing shelf presence and consumer attraction. Our tins are also environmentally friendly, aligning with current trends in sustainable packaging. They are reusable and recyclable, supporting your company's green initiatives. Choose from a variety of sizes and shapes to fit your specific needs, whether for cannabis packaging, pharmaceutical containers, or any other products requiring stringent safety measures. By choosing [Your Company Name], you are opting for child-resistant packaging that protects your products and your end users. Our tins meet all regulatory requirements for child-resistant effectiveness, providing you with peace of mind and your customers with safe, accessible solutions. Keywords: child-resistant tin packaging, child-proof tins, child-safe packaging, custom tin packaging, sustainable packaging, cannabis packaging, pharmaceutical containers.](https://goldentinbox.com/wp-content/uploads/2024/05/CR-tin-goldentinbox-2-s.webp)