Discover our Custom Wholesale Large Standard Size Metal Lunch Tin Boxes with Handle—ideal for durable, stylish packaging needs. Crafted from high-quality tinplate, these metal lunch boxes are perfect for both personal use and commercial branding. With customization options available, they’re designed to meet specific brand requirements, making them a standout choice for unique packaging solutions. As a trusted Custom Tin Lunch Boxes Manufacturer, provides high-quality wholesale solutions that combine functionality with a vintage appeal. Choose our metal packaging for a reliable, long-lasting option that enhances brand presentation. Explore wholesale options today and elevate your packaging game with these custom tin lunch boxes.

Top-Selling Large Lunch Packaging Tin for Bulk Orders

Discover our best-selling Tins, favored by Importer, wholesalers, distributors, and retailers for their durability and Quality performance. Perfect for bulk orders and custom requirements.

General Applications of Metal Tins Packaging

Metal tin can packaging is widely used across various food categories, including popcorn, chocolates, biscuits, candies, tea, spices, and more. It is also commonly utilized in everyday categories such as cosmetics, toys, candles, tobacco, gifts, skincare, and similar products.

Our tins come in a variety of sizes and styles, including round, rectangular, and irregular shapes. We offer multiple appearance options: windowed or non-windowed, concave or non-convex, stackable or non-stackable, as well as four-color or spot-color designs.

Additionally, different functional options are available, such as welded or non-welded, and child-resistant or non-child-resistant. These features strongly enhance our clients’ ability to meet their packaging demands.

Why Choose Tins for Packaging?

Tins are a top choice for packaging due to their durability, eco-friendliness, and ability to preserve product freshness. As a sustainable packaging solution, tins are 100% recyclable and offer excellent protection against light, moisture, and air, making them ideal for tea,cookie,spice,chocolate,coffee,toys,cosmetic, promotion etc, customizable design options also enhance brand visibility. Choosing tins ensures both quality and longevity for your products.

Efficient Tinplate Packaging Box Prodcution Schedule

At Golden Tin, we understand the essence of time in the competitive market. Our streamlined production process guarantees not just timely delivery but also the adaptability to meet your specific demands, ensuring your shelves are stocked with best tin packaging boxes for your packaging needs.

We promise a production schedule that works with your business cycle with our advanced manufacturing methods and strong supply chains, offering flexibility and reliability. This gives you peace of mind when planning your product launches and sales, since you know your orders will arrive on time.

Our strickly quality control ensures consistency in every order, making us a trusted partner for your packaging solutions.

Enjoy the ease of working with a partner that respects your time and business and gives you all-in-one ways to impress your customers with top rated tinware season after season.

Step 1: Material Preparation (3-7 days)

This involves sourcing high-quality raw materials such as tinplate and aluminum sheets, as well as coatings or finishes such as non-stick coatings. The duration depends on the raw material specification and other relative printing process requirements.

Step 2 : Tinplate Printing ( 7-15 days )

Once the materials are prepared, the next step is printing process according to different clients’ designs requests to reach the best printing effects to meet clients requestment.

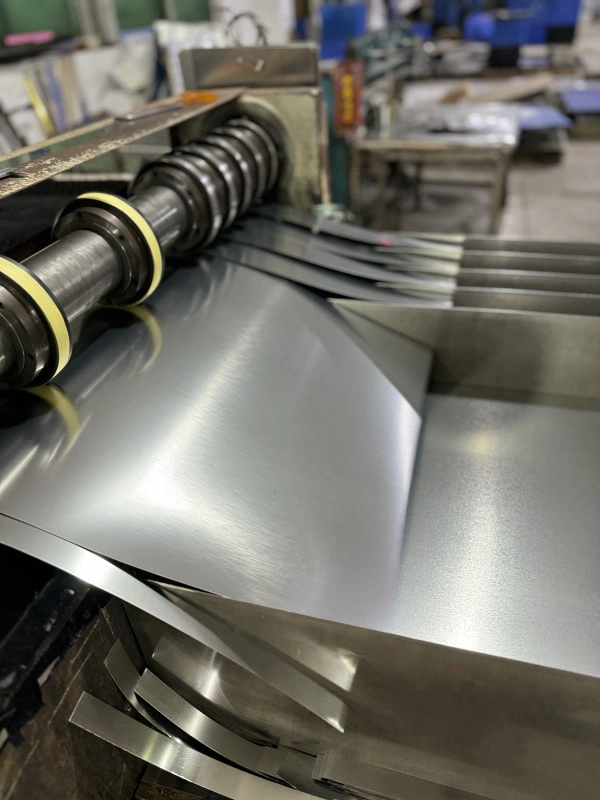

Step 3: Cutting Tinplate ( 1-5 days)

Once the printed materials are prepared, the next step is cutting tinplate according to the shapes our clients ordering.

Step 4: Forming and Bending Tinplate (5-10 days)

The cut tinplate pieces are then formed into the shapes needed for the tin box, such as the base, lid, and sides. This is done using molds and presses to achieve the desired dimensions and design.

Step 5: Assembling | Packaging ( 3-10 days)

After the metal baking pans are formed, they will undergo several surface treatment processes, including degreasing, pickling, and phosphating. These processes help to remove any impurities and prepare the surface of the metal for painting.

Step 6: Ready for shipping

All of our tins after inspection and packed then to our warehouse wait for loading to different buyers over the world.

Case Analytics

Tins have been a popular choice for packaging due to their robust nature and protective qualities. They safeguard contents from moisture, air, and light, thereby extending shelf life and maintaining product quality. Additionally, tins are fully recyclable, supporting environmental sustainability. Their versatility allows for creative designs, making them an attractive option for branding and enhancing the visual appeal of products on shelves.

FAQ

Common questions about Golden tins for your reference. Any further questions about our tins, don’t hesitate to contact us!

Our custom tins are perfect for a wide range of products including luxury items, food, cosmetics, candles, and promotional gifts. Our experience with renowned brands across various sectors ensures that we can meet the specific packaging needs of any industry.

We offer extensive customization options including a variety of shapes, sizes, and lid styles. Clients can choose from finishes such as matte, glossy, or embossed, and we can accommodate intricate tinplate designs to align with your brand identity.

The design process starts with understanding your requirements and vision. Clients can submit their own artwork or collaborate with our design team to create custom graphics. We then provide prototypes for approval before moving to full-scale production.

Our minimum order quantities vary depending on the size and customization details of the tins, but we strive to accommodate both large-scale and smaller, boutique orders to meet diverse client needs.

The typical lead time ranges from a few weeks to several months, depending on the complexity of the order and current production schedules. We work diligently to meet your timelines while maintaining the highest quality standards.

Sustainability is a cornerstone of our operations. We use eco-friendly materials and manufacturing processes that minimize environmental impact, ensuring that our tins are both durable and recyclable.

Yes, we provide samples so you can assess the quality and design of our tins. Samples may be free or involve a nominal charge, depending on the customization and design efforts involved.

All tins are securely packaged using protective materials that prevent damage during transit. Our packaging ensures that your custom tins arrive in pristine condition, ready for immediate use.

We offer various shipping options, including domestic and international freight services. Shipping costs are calculated based on the order size and destination. We ensure that all shipments are securely packed and cost-effective.

![CR tin Secure and Stylish Child-Resistant Tin Packaging for Safe Storage At [Your Company Name], we specialize in innovative child-resistant tin packaging solutions designed to meet the highest safety standards while enhancing your brand's visual appeal. Our child-proof tins are perfect for a variety of industries, including pharmaceuticals, cannabis, and household products, ensuring that safety and functionality go hand in hand. Our child-resistant containers are crafted with precision, employing a patented locking mechanism that is simple for adults to use but challenging for children, effectively reducing the risk of accidental access. Each tin is constructed using high-quality, durable materials that offer excellent protection against contamination and damage, making them ideal for both child-safe packaging and adult use. Safety is at the forefront of our design process, but we do not compromise on aesthetics. We offer custom tin packaging options that allow you to tailor the look and feel of your products to match your brand identity. With advanced printing and embossing techniques, your packaging is not just secure but also visually appealing, enhancing shelf presence and consumer attraction. Our tins are also environmentally friendly, aligning with current trends in sustainable packaging. They are reusable and recyclable, supporting your company's green initiatives. Choose from a variety of sizes and shapes to fit your specific needs, whether for cannabis packaging, pharmaceutical containers, or any other products requiring stringent safety measures. By choosing [Your Company Name], you are opting for child-resistant packaging that protects your products and your end users. Our tins meet all regulatory requirements for child-resistant effectiveness, providing you with peace of mind and your customers with safe, accessible solutions. Keywords: child-resistant tin packaging, child-proof tins, child-safe packaging, custom tin packaging, sustainable packaging, cannabis packaging, pharmaceutical containers.](https://goldentinbox.com/wp-content/uploads/2024/05/CR-tin-goldentinbox-2-s.webp)