Custom Square Stackable Cookie Tins | Personalized Cookie Tin Boxes – Goldentinbox

Discover our Custom Square Stackable Cookie Tins from Goldentinbox, designed to keep your cookies fresh and stylishly presented. These personalized cookie tin boxes are perfect for any occasion, offering both functionality and aesthetic appeal. Made with high-quality materials, our stackable cookie tins ensure durability and easy storage.

Enhance your brand with custom designs and logos, making these tins ideal for gifts or retail packaging. Choose Goldentinbox for your custom packaging needs and elevate your cookie presentation today!

Top-Selling Packaging Tin for Bulk Orders

Discover our best-selling Tins, favored by Importer, wholesalers, distributors, and retailers for their durability and Quality performance. Perfect for bulk orders and custom requirements.

General Applications of Metal Tins Packaging

Metal tin can packaging is widely used across various food categories, including popcorn, chocolates, biscuits, candies, tea, spices, and more. It is also commonly utilized in everyday categories such as cosmetics, toys, candles, tobacco, gifts, skincare, and similar products.

Our tins come in a variety of sizes and styles, including round, rectangular, and irregular shapes. We offer multiple appearance options: windowed or non-windowed, concave or non-convex, stackable or non-stackable, as well as four-color or spot-color designs.

Additionally, different functional options are available, such as welded or non-welded, and child-resistant or non-child-resistant. These features strongly enhance our clients’ ability to meet their packaging demands.

包装に缶を選ぶ理由

Tins are a top choice for packaging due to their durability, eco-friendliness, and ability to preserve product freshness. As a sustainable packaging solution, tins are 100% recyclable and offer excellent protection against light, moisture, and air, making them ideal for tea,cookie,spice,chocolate,coffee,toys,cosmetic, promotion etc, customizable design options also enhance brand visibility. Choosing tins ensures both quality and longevity for your products.

Efficient Tinplate Packaging Box Prodcution Schedule

At Golden Tin, we understand the essence of time in the competitive market. Our streamlined production process guarantees not just timely delivery but also the adaptability to meet your specific demands, ensuring your shelves are stocked with best tin packaging boxes for your packaging needs.

We promise a production schedule that works with your business cycle with our advanced manufacturing methods and strong supply chains, offering flexibility and reliability. This gives you peace of mind when planning your product launches and sales, since you know your orders will arrive on time.

Our strickly quality control ensures consistency in every order, making us a trusted partner for your packaging solutions.

Enjoy the ease of working with a partner that respects your time and business and gives you all-in-one ways to impress your customers with top rated tinware season after season.

Step 1: Material Preparation (3-7 days)

This involves sourcing high-quality raw materials such as tinplate and aluminum sheets, as well as coatings or finishes such as non-stick coatings. The duration depends on the raw material specification and other relative printing process requirements.

Step 2 : Tinplate Printing ( 7-15 days )

Once the materials are prepared, the next step is printing process according to different clients’ designs requests to reach the best printing effects to meet clients requestment.

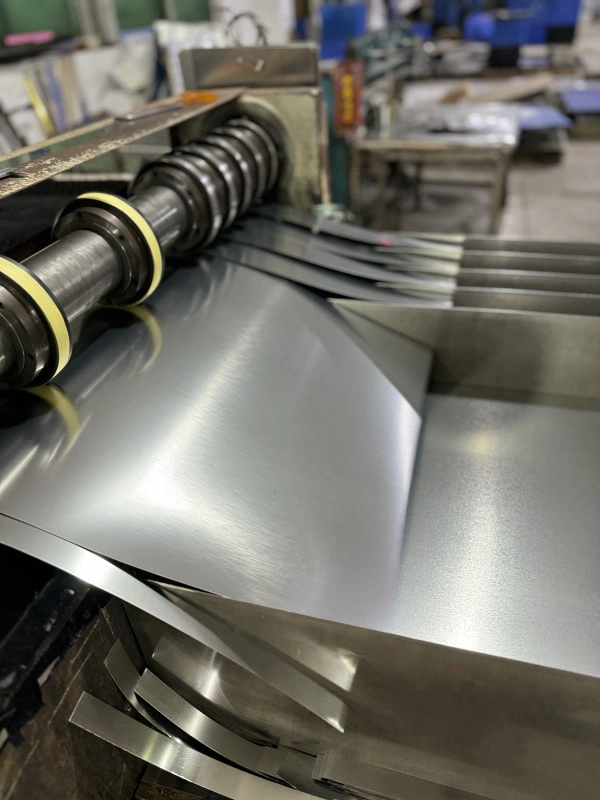

Step 3: Cutting Tinplate ( 1-5 days)

Once the printed materials are prepared, the next step is cutting tinplate according to the shapes our clients ordering.

Step 4: Forming and Bending Tinplate (5-10 days)

切断されたブリキ片は、ベース、蓋、側面などのブリキ箱に必要な形状に成形されます。これは、金型とプレスを使用して行われ、目的の寸法とデザインを実現します。

Step 5: Assembling | Packaging ( 3-10 days)

After the metal baking pans are formed, they will undergo several surface treatment processes, including degreasing, pickling, and phosphating. These processes help to remove any impurities and prepare the surface of the metal for painting.

Step 6: Ready for shipping

All of our tins after inspection and packed then to our warehouse wait for loading to different buyers over the world.

ケース分析

缶はその堅牢な性質と保護特性により、包装によく選ばれてきました。内容物を湿気、空気、光から保護することで、保存期間を延ばし、製品の品質を維持します。さらに、缶は完全にリサイクル可能であり、環境の持続可能性をサポートします。多用途性により創造的なデザインが可能となり、ブランディングの魅力的な選択肢となり、棚にある商品の視覚的な魅力を高めます。

よくある質問

ゴールデン缶に関するよくある質問をご参照ください。缶についてさらにご質問がございましたら、お気軽にお問い合わせください。

当社のカスタム缶は、高級品、食品、化粧品、キャンドル、販促ギフトなど、幅広い製品に最適です。さまざまな分野の有名ブランドとの経験により、あらゆる業界の特定のパッケージングのニーズを満たすことができます。

さまざまな形状、サイズ、蓋のスタイルなど、幅広いカスタマイズ オプションを提供しています。お客様はマット、光沢、エンボス加工などの仕上げからお選びいただけます。また、お客様のブランド アイデンティティに合わせた複雑なブリキのデザインにも対応できます。

設計プロセスは、要件とビジョンを理解することから始まります。クライアントは独自のアートワークを提出したり、デザインチームと協力してカスタムグラフィックを作成したりできます。その後、本格的な生産に移行する前に、承認のためにプロトタイプを提供します。

最小注文数量は缶のサイズやカスタマイズの内容によって異なりますが、お客様の多様なニーズを満たすために、大規模な注文から小規模なブティック注文まで対応できるよう努めています。

通常のリードタイムは、注文の複雑さと現在の生産スケジュールに応じて、数週間から数か月の範囲です。当社は最高の品質基準を維持しながら、お客様の納期に間に合うように熱心に取り組んでいます。

持続可能性は当社の事業の基礎です。当社では、環境への影響を最小限に抑える環境に優しい材料と製造プロセスを使用し、缶の耐久性とリサイクル性を確保しています。

はい、缶の品質とデザインを評価できるようにサンプルを提供しています。サンプルは、必要なカスタマイズや設計作業に応じて、無料または少額の料金が発生する場合があります。

すべての缶は、輸送中の損傷を防ぐ保護材を使用して安全に梱包されています。当社の梱包により、カスタム缶はすぐに使用できる状態で到着します。

当社では、国内および国際貨物サービスを含むさまざまな配送オプションを提供しています。送料は注文サイズと配送先に基づいて計算されます。当社はすべての荷物が安全に梱包され、コスト効率が高いことを保証します。

![CR 缶 安全に保管できる安全でスタイリッシュな子供用の缶パッケージ [貴社名] では、最高の安全基準を満たすと同時に貴社のブランドの視覚的魅力を高めるように設計された、子供用の安全な缶パッケージ ソリューションを専門としています。当社のチャイルドプルーフ缶は、医薬品、大麻、家庭用品などのさまざまな業界に最適で、安全性と機能性が確実に両立します。当社の子供用安全コンテナは精密に作られており、大人にとっては簡単だが子供にとっては使いにくい特許取得済みのロック機構を採用しており、誤ってアクセスするリスクを効果的に軽減します。各缶は、汚染や損傷から優れた保護を提供する高品質で耐久性のある素材を使用して作られているため、子供が安全に使用できる包装と大人の使用の両方に最適です。安全性は当社の設計プロセスの最前線にありますが、美観についても妥協しません。当社では、ブランド アイデンティティに合わせて製品の外観と雰囲気をカスタマイズできるカスタム缶パッケージ オプションを提供しています。高度な印刷およびエンボス技術を使用することで、パッケージは安全であるだけでなく、視覚的にも魅力的となり、店頭での存在感と消費者の魅力を高めます。当社の缶は環境にも優しく、持続可能な包装の現在のトレンドに沿っています。これらは再利用可能でリサイクル可能であり、企業の環境への取り組みをサポートします。大麻の包装、医薬品の容器、または厳格な安全対策を必要とするその他の製品など、特定のニーズに合わせてさまざまなサイズや形状からお選びいただけます。 [貴社名] を選択すると、製品とエンドユーザーを保護する子供が安全なパッケージを選択することになります。当社の缶は、小児に対する耐性に関するすべての規制要件を満たしており、お客様とお客様の顧客に安全でアクセスしやすいソリューションを提供します。キーワード: 子供に安全な缶包装、子供に安全な缶、子供に安全な包装、カスタム缶包装、持続可能な包装、大麻包装、医薬品容器。](https://goldentinbox.com/wp-content/uploads/2024/05/CR-tin-goldentinbox-2-s.webp)